Chipboard screws countersunk head Torx (steel hardened zincplated) SilverMate

As a unique screw in the market, the SilverMate Next generation screws have their own optimum pitch and specific characteristics for each length and diameter, which are applied lightly or heavily.

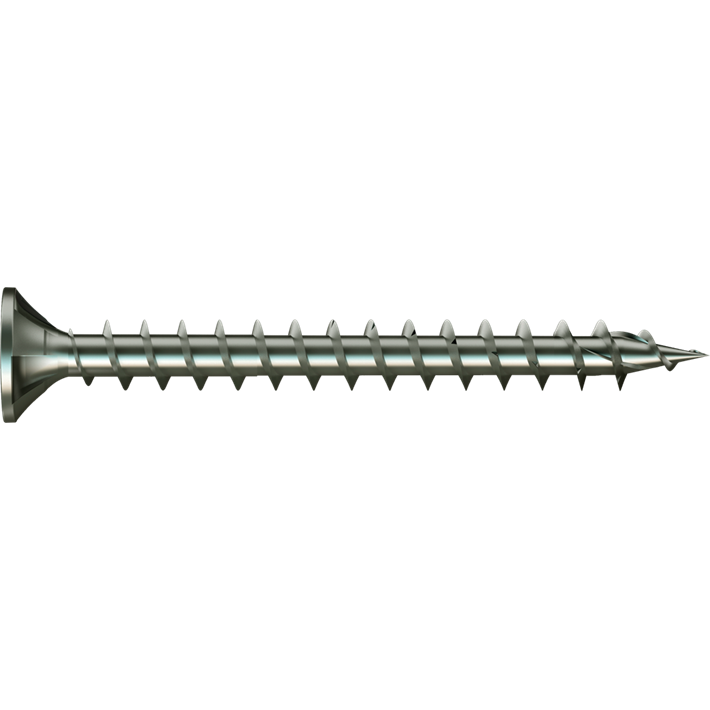

Short screws, on the other hand, have a smaller pitch in order to achieve a high pull-out value. The longer screws, from 60mm to 200mm, have an increasing pitch, so that these screws can be screwed in faster. Today's screw tops are getting stronger and faster screwing in saves a lot of time.

The focus of the SilverMate Next generation is focused on 4 properties that are at least equal to the best-known A-brands:

1) With low starting pressure, the SilverMate Next generation screw goes into the wood from the first revolutions. Particularly with screws with a type 17 milling point, much more pressure is often required.

2) SilverMate Next generation screws are clearly less likely to break at high screw load. Diameter 4.0, 4.5 and 5.0 are reinforced.

3) SilverMate Next generation screws are noticeably lighter than almost all other brands on the market. The screw-in resistance is 25-30% lower, especially with the longer sizes in 5.0 and 6.0 diameter.

4) SilverMate Next generation screws have a low splitting risk due to the special milling thread at the tip when the screw is used near the head end of a plank or batten.

Finally, a change has been made to the packaging of the SilverMate Next generation. The familiar box has remained the same, but now it no longer has a viewing window, so that no plastic is used during waste separation.

Short screws, on the other hand, have a smaller pitch in order to achieve a high pull-out value. The longer screws, from 60mm to 200mm, have an increasing pitch, so that these screws can be screwed in faster. Today's screw tops are getting stronger and faster screwing in saves a lot of time.

The focus of the SilverMate Next generation is focused on 4 properties that are at least equal to the best-known A-brands:

1) With low starting pressure, the SilverMate Next generation screw goes into the wood from the first revolutions. Particularly with screws with a type 17 milling point, much more pressure is often required.

2) SilverMate Next generation screws are clearly less likely to break at high screw load. Diameter 4.0, 4.5 and 5.0 are reinforced.

3) SilverMate Next generation screws are noticeably lighter than almost all other brands on the market. The screw-in resistance is 25-30% lower, especially with the longer sizes in 5.0 and 6.0 diameter.

4) SilverMate Next generation screws have a low splitting risk due to the special milling thread at the tip when the screw is used near the head end of a plank or batten.

Finally, a change has been made to the packaging of the SilverMate Next generation. The familiar box has remained the same, but now it no longer has a viewing window, so that no plastic is used during waste separation.

Article number:

814.30030.1022

Type number:

814

Article GTIN:

8712543649814

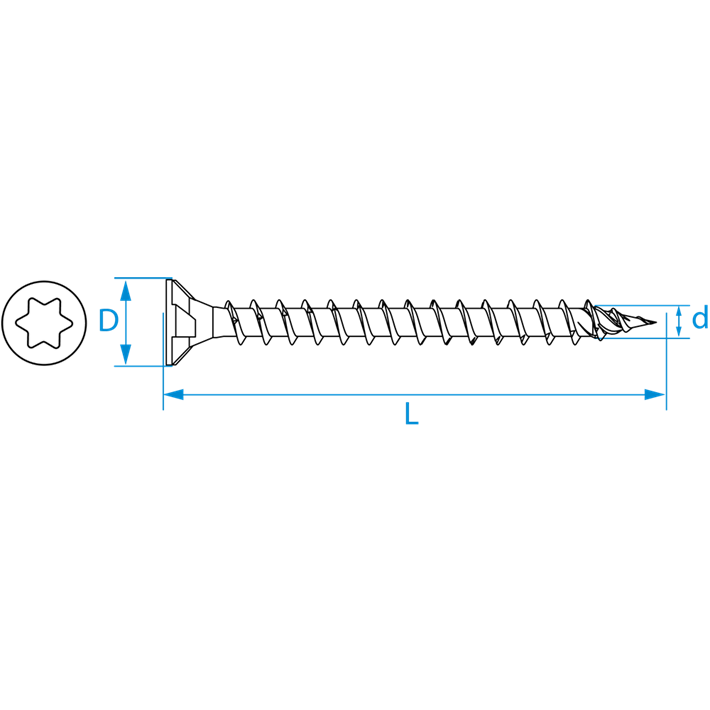

| d | 3.0 mm |

| L | 30 mm |

| L1 | - mm |

| Version | full thread |

| Drive | TX-10 |

| Packaging | box |

| Head shape | countersunk head |

| Material/Surface treatment | steel hardened zincplated |

| Pack | 200 pcs |

| Amount per outer box | 6000 pcs |